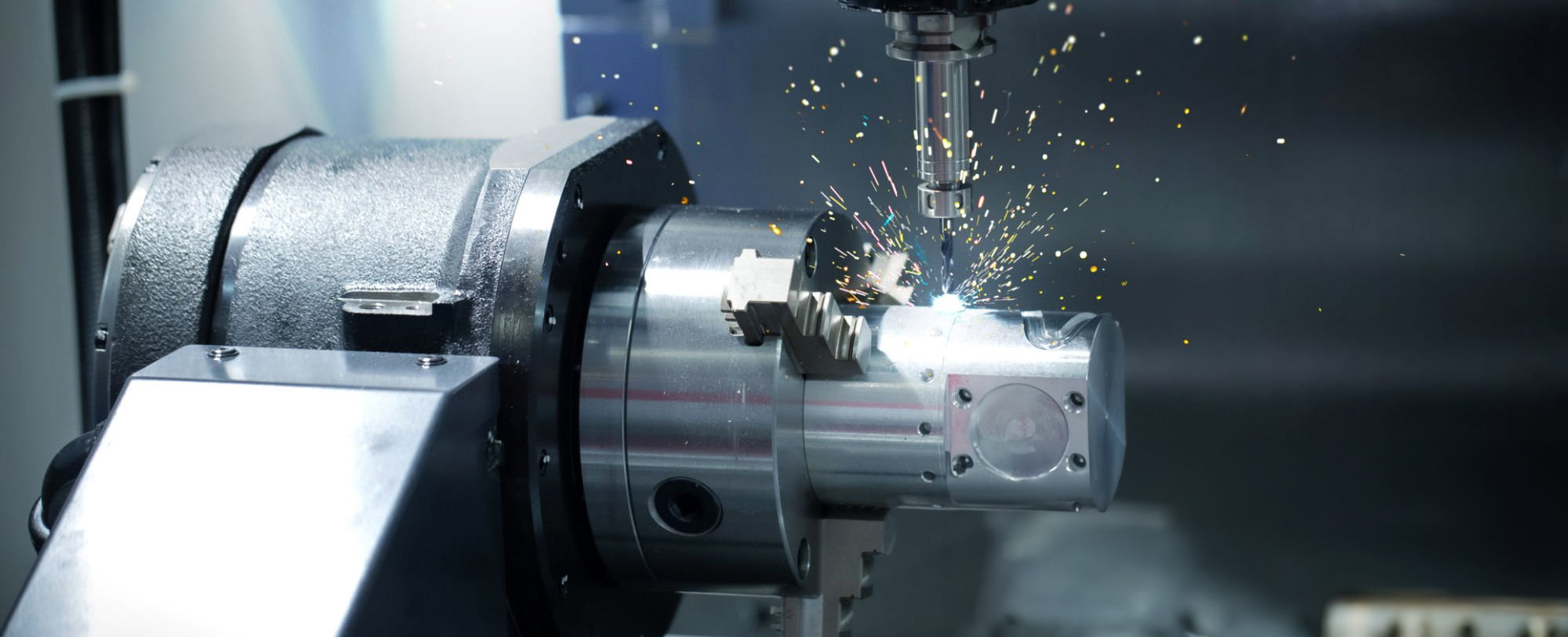

For OEMs interested in precision machining solutions, through our network of proven industrial partners, D.P. Riggins brings extensive capabilities in CNC and Screw Machine-produced component parts. Our core services include turning, milling, drilling/tapping, thread rolling, thread whirling, centerless grinding, gun drilling, wire EDM and harperizing.

From a 140,000sf climate-controlled shop floor, we offer state-of-the-art equipment and a production team of well over 100 associates.

Industrial Segments Served:

Aerospace, automotive, electrical, industrial switch, medical, plumbing, power transmission, valve and welding.

Certifications:

ISO 9001:2015 Certificate of Quality System Assessment

ISO 12485: 2016 Medical Device Quality Management

Our capabilities include:

CNC Turning

We feature the most respected names in machine tooling, including Nakamura, Doosan, Ganesh, Samsung, Mori Seiki, Yam Seiki, Citizen, Tsugami and Okuma. Capabilities from single-spindle gang tool machines, to twin spindle, twin-turret 8-axis chucker and bar machines.

| # Axes: | Up to 8 |

| Tolerances: | .0002” |

| Max Bar Stock Diameter: | 14 inches |

Swiss Turning

Often used in aerospace, medical, automotive and electronics industry segments, Swiss machining delivers the tightest tolerances required for intricate parts. Our trained team works with Citizen and Tsugami machining centers.

| # Axes: | Up to 13 |

| Tolerances: | .0002” |

| Max Bar Stock Diameter: | 32mm |

| Max Length: with Guide Bushing: | 320 mm / 12.59″ |

| Max Length: w/o Guide Bushing: | 70 mm / 2.74 |

Screw Machining

Our screw machines offer a cost-effective and fast machining solution to a broad segment of industries. We maintain more than 70 screw machines with single, six, and eight spindles; chucking; thread rolling; pick-off and back finishing; high pressure coolant and more.

Specific capabilities include: Boring, drilling, knurling, milling, reaming, broaching, turning, internal threading, external threading and roll stamping.

| # Spindles: | Up to 8 |

| Tolerances: | .001” |

| Max Bar Stock Diameter: | 2.625″ |

CNC Milling

We offer expertise in medium- and high-run production, delivering the precise tolerances, finishes and complex geometries needed. With both 4- and 5-axis vertical milling centers, we can process a range of precision parts from raw stock, as well as castings and forgings. We work with a broad range of materials, including aluminum, stainless steel, brass, plastics, steel and many exotic materials.

| # Axes: | 4 and 5 |

| Tolerances: | .0002” |

| Largest Table Size: | 1300×750 |

| Max Spindle Speed: | 15000 rpm |

| Tool Storage Capacity: | 30 |

| Travel (X/Y/Z) (mm): | 1050/570/510 |

Gun Drilling

Nakamura and Doosan CNC lathes have gun drilling capability, but our DeHoff twin-spindle gun drilling technology offers 500” max o.d. drill and has 18 inches of stroke. Concentricity is .001” per 1.00” length of cut.

Wire EDM

Having our own in-house wire EDM department allows us to maintain the level high-dimensional accuracy our customers expect throughout the facility. We process tooling that meets your exact requirements.

| Tolerances: | .0001” |

| Max work height (flush/submerged): | 8″ |

| Max work weight (flush/submerged): | 660 lb |

| Table Size: | 23.6″ x 15.7″ |

| X Axis Travel: | 11.8″ |

| Y Axis Travel: | 7.87″ |

| Z Axis Travel: | 7.87″ |

| U/V Axis Travel: | 3.14″ |

| Taper Capacity: | +/- 20 deg |

| Tank Capacity: | 138 Gal |

| Wire Diameter: | 0.006″ – 0.012″ |

| Wire Tension: | 0.66 – 5.06 lbs |

| Wire Feed Speed: | 9.8″/sec |