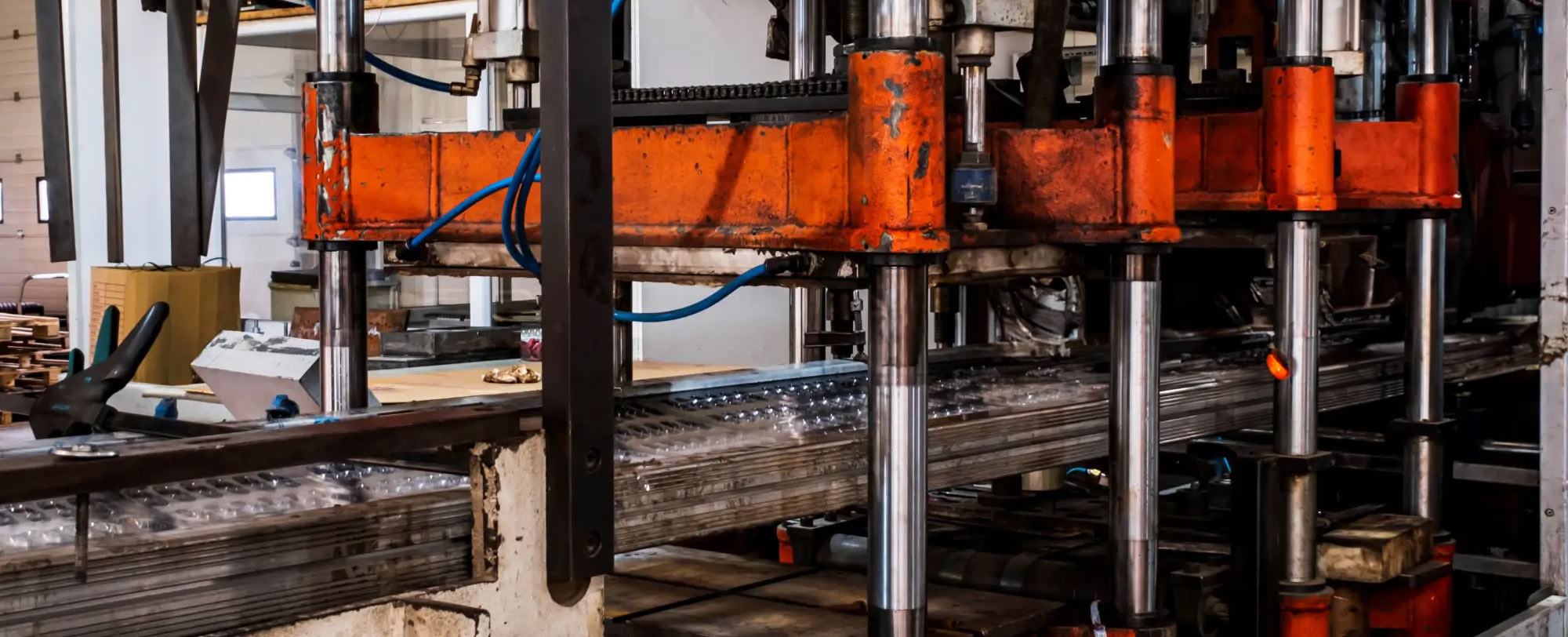

D.P. Riggins partners with a vertically integrated U.S. thermoforming manufacturer offering comprehensive in-house capabilities, including sheet extrusion and extrusion film lamination. With over five decades of experience, our partner specializes in vacuum forming, pressure forming and advanced twin-sheet forming. These capabilities provide OEMs with a broad spectrum of processes ideal for producing durable, structurally complex parts that incorporate high aesthetic requirements.

Very likely our most critical advantage is an experienced engineering team, comprising over 30 degreed professionals. This allows us to collaborate directly with our OEM engineering counterparts to optimize part design for manufacturability, performance and cost-efficiency.

Operating from four thermoforming facilities that together comprise more than 570,000 SF of manufacturing space, we provide critical applications for a diverse mix of industrial segments. A wide range of thermoplastics, including HDPE, TPO, ABS (with high-gloss acrylic or low-gloss Korad caps) and polycarbonate, can be specified based on specific performance requirements such as impact resistance, UV stability and thermal properties.

Precision CNC trimming ensures tight tolerances and faster cycle times. Value-added services such as painting, foam filling and hardware installation put us in an elite category of thermoformers with the kind of comprehensive capabilities that keep quality, pricing and turnaround under one roof.

We maintain ISO 9001 certification across all facilities, underscoring a commitment to quality management and continuous improvement. A customer-centric approach ensures that each project meets exact specifications, delivering consistent quality and reliability for demanding OEM applications.

Markets Regularly Served:

Agriculture

Industrial Products

Medical / Healthcare

Powersports

Refrigeration